Article by: 95FIM5

Preface/History: I did this work while my vehicle was on four jack stands and the wheels and brakes were off, that shouldn’t affect this DIY but keep that in mind.

Also this is a good time to refresh the upper control arms and the sway-bar bushings and hardware since you will be unbolting them.

The x-brace was added to later E31 models was, in my opinion most likely due to chassis flex which could be the result of the lack of a B-pillar which was a defining design feature of the “pillar less coupe”.

The E31 X brace is extremely similar to the later E36 x-brace but of much more substantial construction and incorporating two additional mounting points on the trailing portion of the x “arms”, see below pics of the E31 (left) and E36 (right) braces.

Above: 850CSI vs. e36 x-brace

Tools and Materials:

- Hacksaw or Dremel Tool with cutoff wheels

- Files

- Masking tape

- Safety glasses

- Wurth Zinc Rich Weld Thru Primer (Or whatever you wish I prefer this one)

- Wurth Matte Black Spray Paint (Again or whatever you want)

- Wurth Cavity Protection Spray (I’m not going deeper on this one)

- Loctite 246

- 22mm Socket

- 17mm Socket

- 15mm Socket

- 10mm Socket

- 22mm Wrench

- 17mm Wrench

- 15mm Wrench

- 10X1.5mm tap or thread chaser

- 14X1.5mm tap or thread chaser

- Tap handle

- Torque wrench

- Ratchets

Part Numbers and Quantities:

| BMW Part Number | Description | Price | QTY | Sub-Total |

| 31111140614 | X-Brace | 1 | ||

| 31111140576 | Adapters | 2 | ||

| 33331132413 | Hex bolt M10X20 | 6 | ||

| 07119914851 | Hex bolt M14X1.5X90 | 4 | ||

| 33311125916 | Washer | 4 | ||

| 31111130687 | Reduced shaft bolt M10X150 | 2 | ||

| 07119904198 | Washer | 2 | ||

| 32211137537 | Heat shield front | 1 | ||

| 32211141270 | Heat shield rear | 1 | ||

| 07119915017 | Hex bolt with washer M6X12 | 2 | ||

| 52201975880 | Blind rivet nut | 2 | ||

| 07119903844 | Hex bolt with washer M6X16 | 2 | ||

| 07129901668 | Body nut ST6 | 1 | ||

| 07119916967 | Hex head screw ST6 | 1 | ||

| Total |

X-Brace Modification:

This modification is due to the fact that the E34 doesn’t have the “arm” mounting points on the chassis that the later E31’s do but the brace still adds rigidity in the same manner as the E36 x-brace.

The next picture shows what portion of the brace we are removing.

I chose to cut the arms off .25″ from the plate that creates the mounting portion for the sway-bar, this spacing avoids cutting into the weld of the mount point.

I marked my line using masking tape so that I could create a parallel cut with the sway-bar mounting bracket, then using a Dremel tool (Put on your safety glasses!!) and a cutoff wheel lightly scored the area for my cut.

Here is the finished cut:

You next want to file any sharp corners and burs off the cut.

To finish the modification clean off any cutting grit and metal shavings and remove any oils on the part prior to painting,

I chose to use Wurth products with two coats of Zinc primer followed by two coats of black paint.

Here is the x-brace with the modifications finished.

Dis-assembly:

First off on flat stable ground properly chock the rear wheels and apply the emergency brake.

Lift the front of the vehicle so that you are able to place jack stands under the car at the factory jacking positions.

I personally use the boxed sections of the uni-body to lift at but my jack has a wide rubber pad that helps to spread the load and not damage the under body coating; use your own judgement and be careful!!!

Once the vehicle is safely on jack stands be sure to check the rear chock placement again and double check to make sure the vehicle is stable.

Remove the under engine plastic cladding and the air guide to the transmission.

Locate the front sway bar and proceed to unbolt its end links and chassis mounting points. (My bar was already off since Ive been working on a new mount and bushing setup.) Set the sway bar aside.

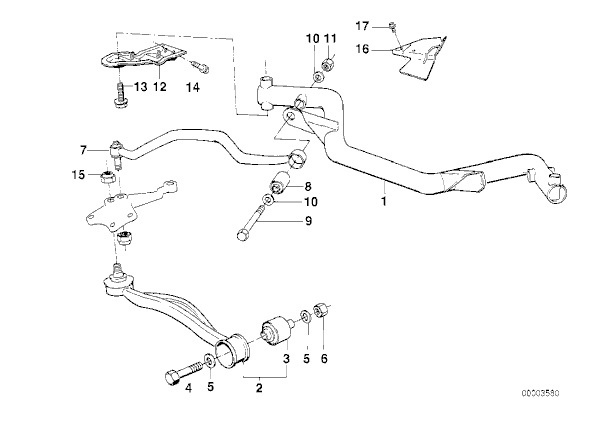

You next want to unbolt the upper control arm #7 from the cross tube which is bolt #9 and nut #11 in the below drawing, these should require a 22mm socket and wrench.

After unbolting the control arm suspend it with wire or zip ties from the spring coil, try and keep it at the installed height this helps when installing the x-brace.

You next unbolt the cross tube by removing #14 on both drivers and passenger sides, should be 4X bolts in total see above drawing.

Finally remove #13 on driver and passenger sides , this will drop the cross tube.

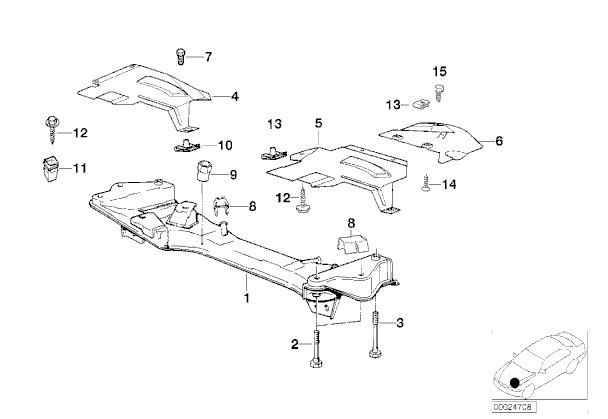

With the cross tube dropped the next parts to remove are the two front sub-frame bolts #3 in the below drawing, I believe these were 17mm but I need to double check.

Now is a good time to clean up the rear mounting points of dirt and grime as well as the pads where the front sub-frame bolts came out of.

Once things are cleaned up chase the chassis mount threads for the M10 and M14 bolts to clean out any rust or previous Loctite.

The last thing to do before assembly is to remove the old heat shields since they will not work with the x-brace, instead you will be using a slightly modified 850csi part.

Remove this heat shield, it is held in place by the bolt attached to the sub-frame directly ahead of the tie rod in the above picture and one bolt that threads into the top of the sub-frame you will need a 10mm socket and ratchet.

It’s easiest to remove the heat shield by pulling it out from in front of the sub-frame.

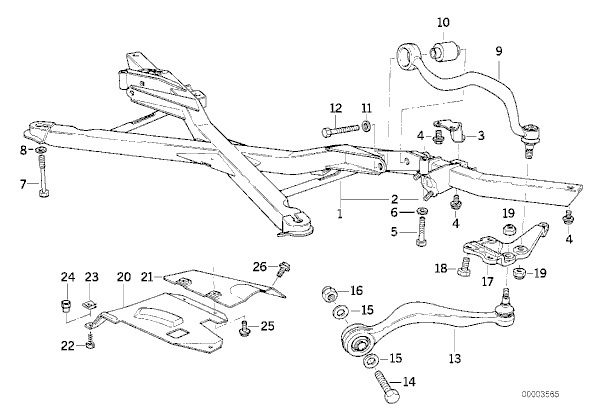

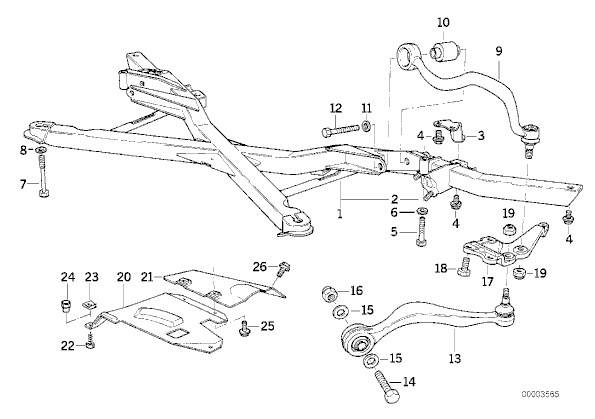

So with all your tools and parts out and ready to go the first parts to be installed are the two adapters (Y shaped black brackets in the above pic, PN 31111140576 qty – 2X with bolts PN: 33331132413 qty – 4X).

I sprayed a small amount of Wurth cavity protection spray on a rag and wiped the face of adapters as well as the chassis to help with rust protection.

Adapter mounting point.

This set of work was done on my back and lifting the x-brace into position off my chest, with all of the hardware easily at hand; if you have someone to help now is a good time.

Apply Loctite 246 to bolts PN 33331132413 4X and use them to fasten the adapter finger tight but still allowing play in the bracket.

Next using bolts 07119914851 2X (The big ones) mount the x-brace in position but not torqued down, you are making sure the Y adapter brackets are aligned with the x-brace mounting holes.

Finally thread the two front sub-frame bolts through the x-brace and front sub-frame and into the chassis to ensure alignment.

If everything aligns well drop the x-brace on to your chest being sure not to move the adapters and torque the adapter bolts to 47NM (This value was based off BMW TIS info, if someone has a better reference Id like that) using a 15mm socket and your torque wrench.

With the adapters torqued to spec now comes the easy part. Apply cavity protection spray to the x-brace and chassis mounting points and apply Loctite 246 to bolts 33331132413 Hex bolt M10X20, 07119914851 Hex bolt M14X1.5X90, and 31111130687 Reduced shaft bolt M10X150.

Next press the x-brace in place and install bolts 07119914851 finger tight and ensuring everything is properly aligned, bolt #5 in the below drawing.

With the x-brace being held by the two M14 bolts (#5 in above drawing) install the two remaining M10X20 Bolts (#4 in above drawing) thru the x-brace and into the adapters.

You should have something that looks like the below pics now for the larger M14 bolts and the smaller M10 bolts.

The next step is to install the longer reduced shaft bolts (#7 in below drawing PN:31111130687 Reduced shaft bolt M10X150) thru the x-brace and front sub-frame, make sure you applied Loctite and torque to 47NM.

Finally torque the adapter to x-brace bolts M10X20 Bolts (#4 in above drawing) to 47NM and the two M14 bolts (#5 in above drawing) to 127NM.

The last thing to install is the new heat shield setup from the 850csi.

Below is a comparison between the new shields and the old shield (I forgot to include a picture with the upper control arm shield which is the reason behind using these since it no longer fits).

Start by mounting the rear heat shield (PN 32211141270) to the x-brace with the M6X16 bolt (PN 07119903844).

Next remove the plastic plug that is on the passenger side of the lowest point of the sub-frame, see below pic circled in red.

With the plug removed now take the forward heat shield (PN 32211137537) and attach the body nut (PN 07129901668) to the leg of the shield like you see in the below pic.

Next using the self tapping screw (PN 07119916967) and going through the hole that you just gained access to by removing the plug attach the front heat shield to the sub-frame.

(It appears that it’s possible to install a rivet nut in the sub-frame replicating the OEM setup but I believe the sub-frame would have to be dropped to do this, thus the body nut use above.)

Once the front and rear heat shields are loosely in place attach the front heat shield to the rear shield using two M6X12 bolts (PN 07119915017), should look like the following:

Last you need to install the blind rivet nut (PN 52201975880) into the chassis in the hexagonal hole in the passenger rail and secure the edge of the front heat shield with a M6X16 bolt (PN 07119903844).

There are two options as I see it to attach the heat shield to the chassis here you can man handle the shield in place or a new hole.

Here is a pic showing the location of the hole on the front shield that needs to be bolted to the chassis via the blind rivet nut.

Still working on a good solution that I will document.

You now have an x-brace with proper heat shields! Finish the install by reinstalling your upper control arms remembering to tighten under load if you have new bushings. Re-install your sway-bar and front engine cover.

Also the x-brace actually opens up room for down pipes for those who care, see below pic: